Text:

MCD16-010_pr_bildverarbeitung_eng.pdf

Pictures (Print, CMYK):

Please feel free to order high resolution images via e-mail.

Pictures (Web, RGB):

2016-08_bildverarbeitung-001-web_mcd.jpg

2016-08_bildverarbeitung-002-web_mcd.jpg

2016-08_bildverarbeitung-003-web_mcd.jpg

2016-08_bildverarbeitung-004-web_mcd.jpg

2016-08_bildverarbeitung-005-web_mcd.jpg

Product Page:

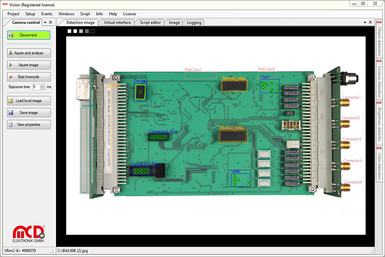

Imaging tools from the product line "Pixline"

MCD Elektronik presents software tool for optical tests

Birkenfeld, Germany, August 16, 2016: The test equipment specialist MCD Elektronik has introduced three solution for visual, industrial quality assurance. Inexpensive, precise and simple to handle. These are the key words to describe the imaging products "MCD Vision", "MCD Sherlock Vision" and "MCD Cognex Vision". These definitions were realized by the "image processing trio" and validated in various projects for the automotive industry. MCD Vision and MCD Cognex Vision are utilized succesfully for optical tests in these sectors. Especially in complexe tests of external or internal mirrors, MCD Vision has established its test security. This tool supports all of the test procedures, from mirror position, arching, measuring and marking of mirrors up to testing of connector contours and illumination. MCD Cognex Vision is characterized by testing accurately with operating device units, parking brake switches and power window assemblies, as well as Wi-Fi modules, boards or contacting strips. MCD Sherlock Vision actually is used for completeness checks of infotainment systems. The software also tests the color of connector plugs, the swash circuit inspection of contacts, the presence of labels and markings, as well as the wholeness of screws. All these imaging packages from MCD are based on a flexible MCD Toolmonitor and a camera system. The corresponding program extensions are available at an extra charge.

Thresholds for the tests are created and the testing of the image acquisition to the analysis are performed within the MCD Toolmonitor. Using an integrated script engine, it is possible to further integrate customized algorithms. The Toolmonitors can be integrated into a large number of applications, like Microsoft Visual Studio® (C#, C++, Visual Basic), Microsoft Office® (e.g. Excel®), OpenOffice® and LabView®. The integration of the Toolmonitors to the universal measurement software MCD TestManager CE is prepared as a standard.

MCD Vision is suitable for the recognition of contours and positions of components and simple models in searching sectors, as well as completeness and symbols checks. As basic features, MCD Vision contains the Toolmonitor Vision, a conventional USB camera for basic elements of imaging and one of the four testing modules "contour detection", "brightness detection", "object detection" or "color detection". With various imaging tools, it is possible to recognize the correct mounting of components, the imprints of pictograms or numerous further quality characteristics of the DUTs. In so-called "live mode" the inserted camera can be adjusted and the camera images can be monitored in real time. Using this mode, the user can sharpen the searching sectors and even check moving objects. For third-party software, MCD Vision can be fully remote controlled. COM/DCOM or .Net-Assembly is used as an interface.

For the MCD Sherlock Vision, the measurement technology specialist has expanded its Toolmonitor program with the "Sherlock Software Interface" from the Canadian manufacturer Teledyne DALSA. With this program imaging projects are invested and defined before the analysis is continued to the Toolmonitor. The Sherlock tools also allow the use of additional visualization and processing functions within the Toolmonitor. The independent imaging software "Common Vision Blox" from Stemmer Imaging, the european leading provider of imaging technology, is integrated into the MCD Sherlock Vision system too. This flexible interface allows the integration of different camera systems. Flexibility and functions, for example, the definition of searching sectors, limits and test values, optical swash circuit inspections and "live mode" had a huge impact for MCD Sherlock Vision to become one of the topsellers of MCD Elektronik.

Sophisticated image processing tasks can be solved by MCD Cognex Vision. This high-end solution includes the smart cameras of provider COGNEX. Imaging algorithms are directly processed in these intelligent cameras. These algorithms and image processing tools are created and automatically retrieved with the easy-to-use configuration interface "EasyBuilder" or the spreadsheet representation in the "In-Sight Explorer" software from Cognex. EasyBuilder, with its quick setup, is applicable for expert users as well as for beginners without programming knowledge. The connection of the In-Sight Explorer to the MCD software allows for presence or position accuracy checking of components as quickly as the testing of quality attributes with pictograms or color control of installed LED's. Furthermore, an external illumination unit can be controlled. "For our MCD Vision series, we work together with the best suppliers to achieve the best results: three excellent software packages for corresponding hardware components for all tasks of imaging test procedures", commented MCD's Software Development Manager Gabor Tinneberg on this imaging trio.

________________________________________________________________________

MCD Elektronik GmbH

Hoheneichstr. 52 | 75217 Birkenfeld | Tel. +49 7231 78 405-49 | Fax +49 7231 78 405-10

Ms. Verena Feidy, verena.feidymcd-elektronik.SPAMPROTECTION.de