Text:

MCD20-006_pr_vts2030-robot-application-eng.pdf

Pictures (Print, CMYK):

Please feel free to order high resolution images via e-mail.

Pictures (Web, RGB):

2020-02-vts2030-robot-application-1-web_mcd.jpg

Project Site:

VTS 2030 - Standard Test Systems

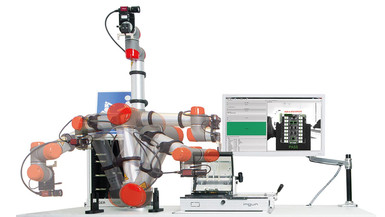

Test system series “VTS 2030” expanded with a collaborating robot

Birkenfeld, Germany, February 25, 2020: MCD Elektronik has already officially released its modular and versatile "VTS 2030" test system series at the productronica 2017 in Munich. Now, the flexible system can also integrate robot applications for test processes within half and fully automated assembly lines.

The prominent feature of the "VTS 2030" is the possibility to modify it for various assemblies and products within very short change-over times. With this development it is possible to respond to the customer’s growing demand for high-end testing facilities, who rather manufacture small quantities of quickly changing variants. The MCD "VTS Rack" is the basis of every system, including a PC and the MCD Universal Measurement System "UMS 1300 ULC". The test adapter with the assembly nest to be tested is located on the table´s surface which can be moved electrically to an ergonomically acceptable work height. The complete test adapter is connected to the "VTS" through a "Pylon" interface. With over 8.000 active licenses, the proven MCD "TestManager CE" is also available for the control, evaluation and documentation of the test performance in the "VTS 2030". Moreover, MCD offers a solution for the customers who prefer to work in a "LabView®" test environment.

With only minimal adjustments, the system can be utilized for functional, End-of-Line, manual functional as well as Boundary Scan tests. By the integration of a collaborating robot, the standard test system can now also be used for test processes within fully automated assembly lines. The robot arm offers the possibility of self-employed gripping of tools or DUTs as well as an automated control of the test adapter. Additionally, there is a camera mounted on the robot which performs optical tests together with an imaging tool from MCD Elektronik inside the test procedure.

Through a combination with modern laser sensors, there is a protective cover around the test system. During a conflict with the protected area, the speed of the multi-axis robot is reduced up to a complete stop if the collision protection with a scanned object or person cannot be ensured.

_________________________________________________________________

MCD Elektronik GmbH

Hoheneichstr. 52 | 75217 Birkenfeld | Germany | Tel. +49 7231 78 405-61 | Fax +49 7231 78 405-10

Mr. Tobias Stange, tobias.stangemcd-elektronik.SPAMPROTECTION.de