Text:

MCD20-001_pr_rugged-keypad-eng.pdf

Pictures (Print, CMYK):

Please feel free to order high resolution images via e-mail.

Pictures (Web, RGB):

2020-03-rugged-keypad-1-web_mcd.jpg

2020-03-rugged-keypad-2-web_mcd.jpg

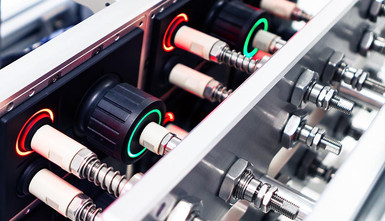

Test system proves a million switching cycles from HDV controllers

Birkenfeld, Germany, March 1, 2020 – The most important aspect of test systems in the modern electronics industry is usually to test as many DUTs as possible in the shortest amount of time. Therefore, short testing times and quick software applications are basically the preconditions for the development of customer-specific test systems from the measurement and automation specialist MCD Elektronik GmbH.

For the already implemented durability test stand for a manufacturer of rugged keypads that are used in heavy duty and special purpose machines, these specifications were intensified. The modular human-machine interfaces, which are installed to road construction, emergency and city cleaning vehicles or also agricultural machines, are tested for duration over a period of 60 days. The mechanical and electrical processes are completely controlled via MCD’s control unit "MIO1616" from its product line CONLINE. The keys of up to six DUTs are simultaneously pressed and all of the switch procedures are tested. There are around one million switching cycles which are handled during the test in a climatic chamber with a simulated temperature environment between -40 °C and +85 °C. Thereby, a long-term high reliability and also functional security even in harsh weather conditions can be guaranteed.

MCD’s project manager Reinhold Szegedi comments on the characteristics of the test system as follows: "To simulate to whole life cycle of approx. ten years during permanently running operations as quick as possible, we had to measure voltage, power consumption and the environment temperature in about five seconds. Furthermore, the functions of pressed and released switches are tested and the relative parameters of all six DUTs are analyzed."

Besides the mechanical fixture with a manual cable and a shielded 6-pol connector, the MCD software controls the majority of the measurement. Various MCD Toolmonitors as well as the universal measurement software "TestManager CE" and the analysis tool "Data Manager" were customized for these exceptional test sequences.

A further special feature was the implementation of the interfaces and communication protocols "CANopen", "J1939" und "CANopen Safety", that were stipulated by the customer. These protocols allow an intelligent control of data transmission between standard devices and standard controls inside of "heavy duty vehicles" and the transmission of commercial vehicle specific data as well as the protection of the whole communication according to European standards.

_________________________________________________________________

MCD Elektronik GmbH

Hoheneichstr. 52 | 75217 Birkenfeld | Germany | Tel. +49 7231 78 405-61 | Fax +49 7231 78 405-10

Mr. Tobias Stange, tobias.stangemcd-elektronik.SPAMPROTECTION.de